1. Faradion's sodium-ion battery. (180 words)

Non-aqueous sodium-ion batteries may be the solution to electric transportation in the future.

A Faradion battery cell consists of three main components: a positive electrode, a negative electrode, and an electrolyte. The positive electrode is made of sodium iron phosphate, which is a stable and low-cost material that provides high capacity and long cycle life. The negative electrode is made of hard carbon, which is a cheap and abundant material that can store sodium ions efficiently. The electrolyte is made of an organic solvent and a sodium salt, which enables fast and reversible sodium ion transport between the electrodes.

A Faradion battery pack consists of multiple cells connected in series or parallel to achieve the desired voltage and capacity. The battery pack also includes a battery management system, which monitors and controls the battery performance and safety. The battery pack can be customized to fit different shapes and sizes depending on the application.

Faradion has tested its sodium-ion batteries extensively in various conditions and scenarios and has demonstrated that they can match or exceed the performance of Lithium-ion batteries in terms of energy density, power density, cycle life, temperature range, and safety.

2. Galvorn carbon nanotube fabric. (186 words)

Galvorn CNT is ready. The new conductive fabric that may revolutionize the world of electronics is here to stay. Embrace the future.

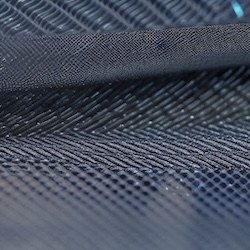

For a while now we've been looking forward to offering a fabric product based on our galvorn CNT yarns. We're happy to announce that we're almost ready to launch that product in our online store and we wanted to give you a look at one of our first fabric prototypes.

This is a six inch by six inch piece of fabric that was made using galvorn CNT yarn. As you can see, it's very flexible and, because it's made from galvorn yarn, it's electrically conductive strong and lightweight. The fabric was made using a criss-crossed pattern of yarn loops that run parallel to the straight edges of the square, so it does not have a lot of ability to stretch in those directions but, as you can see, it does have some ability to stretch along the diagonal direction.

This particular piece of fabric was made using 100-micron diameter galvorn yarn, and has a fabric weight of 80 grams per square meter. As we develop our manufacturing capability we'll offer fabrics with different yarn thicknesses, fabric weight and stretchability, etc.

When we make that product available, we'll have it in a few standard sizes, but we'll also be able to provide galvorn fabric in custom shapes and sizes.

3. Semiconductor oversupply. What happened? (182 words)

'After two years of a chip shortage, we are now finding ourselves in a chip glut. What does a deepening oversupply of semiconductors mean for the industry?' Julie Chang interviews Asa Fitch, Wall Street Journal semiconductors reporter.

Julie Chang: So for those who may not have been following everything going on in the chip industry, can you explain to us why we are suddenly finding ourselves in a chip glut?

Asa Fitch: So there was a surge in demand at the outset of the pandemic and the result of that was chip companies said: ‘oh my gosh! We have to produce as many chips as possible to satisfy this demand!’ And so the people who are making phones and PCs to cater to all that demand they were buying lots of chips. They wanted to stock up essentially, and now demand has fallen off because of the shift back to working in offices and things like that. And those companies, those manufacturers of PCs and phones and things like that are sitting on huge piles of chips. And those manufacturers are responding by saying: ‘You know, we're not going to buy extra chips. We're just going to use what we have and draw down those inventories over time’, but for the chip companies that's bad because it means new orders aren't coming in.